Green Ports: Decarbonizing Ports through Data and make Ports more efficient

Green Ports: Decarbonizing Ports through Data

A look into the maritime shipping industry, the environmental effect of inefficient ports, and how maritime companies use technology to combat this issue.

The International Maritime Organization (IMO) aims to have net-zero shipping emissions in under three decades. Yet, the global shipping industry produces over a gigaton of greenhouse gasses every year. While barriers to advancements for this goal are in no short supply, companies such as Techbinder and LionRock Maritime are already using data to reduce carbon waste.

Maritime Shipping as a Greenhouse Gas Contributor

Port Decarbonization: a Closer Look

Port decarbonization is the process of eliminating environmental impact associated with activities in port, such as tugboat operations, and cargo handling. A key part of this is reducing carbon emissions. The goal is to transition ports to more sustainable and eco-friendly practices, for both local and global communities.

Workboats form a critical part in port decarbonization: A 2002 study in British Colombia and Washington State showed that 28% of port CO2 emissions were from harbor craft and tugboats, making them the second-largest port CO2 contributor, behind container ships.

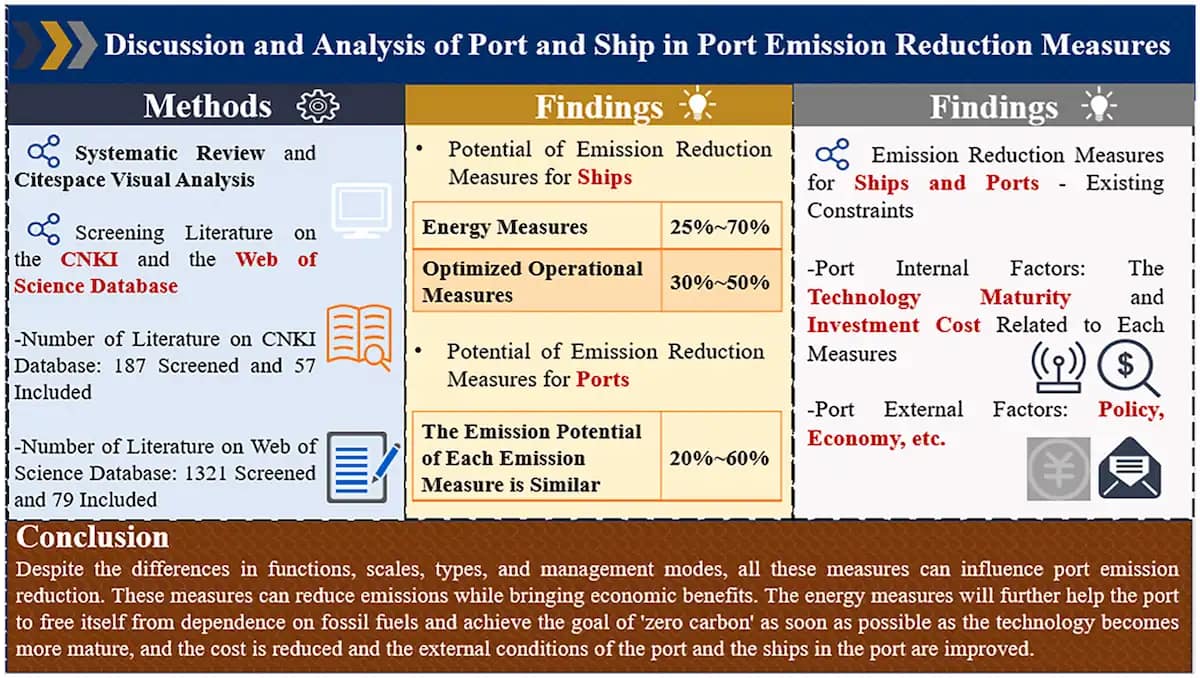

Each step towards port decarbonization is a step towards a shared environmental goal. There are several strategies to achieve this. They include the use of renewable energy sources, more efficient technologies, and improved logistics to minimize emissions and environmental harm. Each solution comes with its own limitations, making some advancements easier to adopt than others. However, one major tactic to reduce emissions, optimizing operations through the use of data, is already in use.

You can schedule a meeting with our representatives and get a consultation on how you can achieve a better operational efficiency: Schedule a Call now.

Technology for the Environment

New technology helps ships pollute less. By using data, shipping companies can learn important things about how their ship’s operation. From granular data about ship’s maneuvering to the utilization and performance of its machinery. The insights gained can help see blind spots and areas for improvement.

While there are similarities between ship types, each of those also has unique characters that requires a tailored optimization approach. While route optimization is (still) considered a major source of fuel optimization and emission reduction for long haul ships to decrease emissions, it is probably less relevant for harbor tugboats. Harbor Tugboats typically operate over relatively short distances within ports, meaning they have less extensive routes to optimize.

Reducing the Carbon Footprint of Tugboats

Today, it is difficult to accurately measure and thereby help decrease the fuel consumption of tugboats. Tugs are designed for a wide range of operations and similarly have a wide spread in their consumption range. Fuel consumption meters, widely used in other shipping segments, have found low adoption in the tugboat sector. The high investment cost as well as the installation from a barrier. Not only are these units expensive, they are also time-consuming to install.

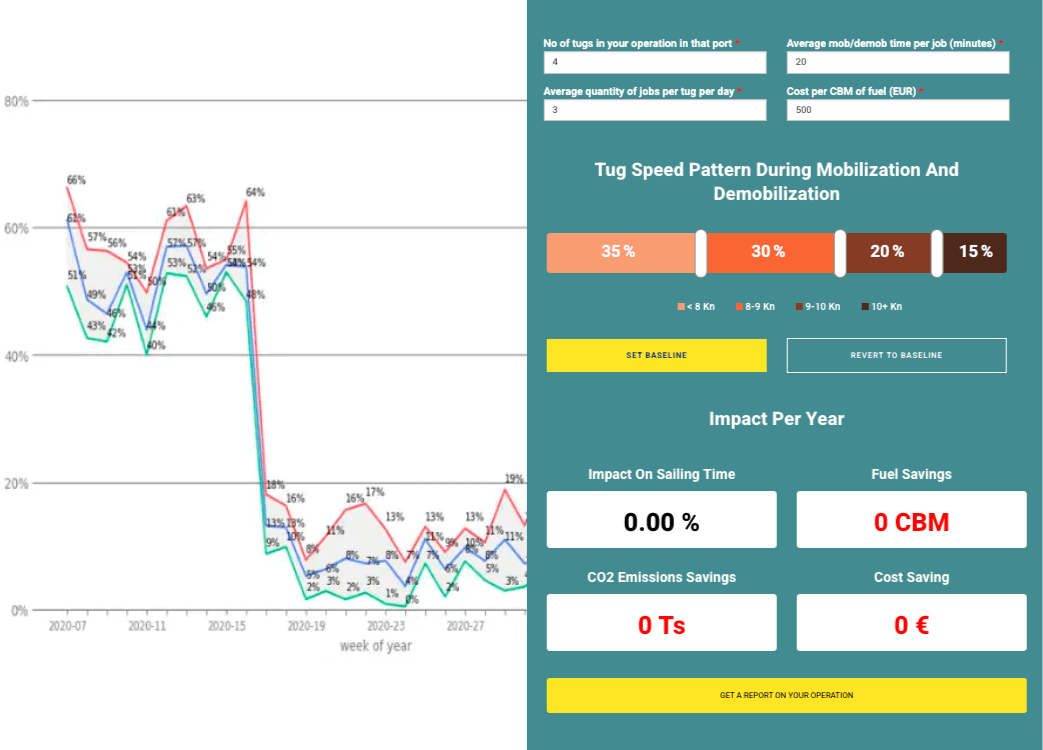

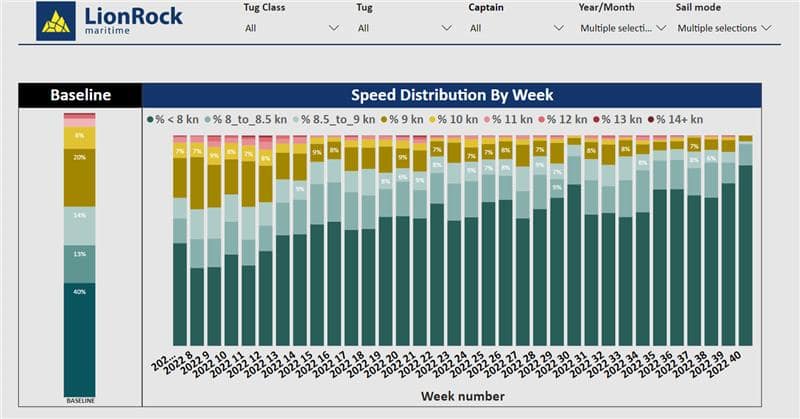

We wanted to address the challenges and promises of accurately measuring fuel consumption without having to rely on expensive fuel consumption meters. In doing so, trying to make data more accessible to tugboat owners, thereby contributing to the goals of port decarbonization and the creation of green ports. LionRock Maritime’s expertise is tug operations data. Applying machine learning and contextual data analysis, LionRock explored correlations between tugboat speeds, power variations, and the unique characteristics of the vessels they assisted, aiming to reduce the shipping carbon footprint. While the direct correlation between tugboat speed and power during light sailing is strong, large variances occur during vessel assistance. LionRock’s innovative models using contextual and engine data separately showed promising results. However, the fusion of these models provided strong predictions of fuel consumption per job, marking a significant breakthrough in accurately estimating tugboat fuel usage, thus contributing to port decarbonization efforts and the reduction of the shipping carbon footprint.

An obstacle to obtaining RPM data lies in its collection from the tug’s engine, necessitating an installation process. To streamline this installation process and ensure the tug remains in operation, LionRock partnered with Techbinder. A tech scale-up from the Netherlands with backing from Schneider Electric that produces and installs industrial grade and cyber-secure data-loggers. LionRock has built a set of software that decodes the data and understands the tugboat operations, helping to turn data into actionable advice. By combining hardware and software, this joint endeavor promises a low-cost solution for assessing tugboat fuel consumption without disrupting tugboat operations, thus advancing the vision of green ports.

The Future of Maritime Shipping

The future of the shipping industry is a low carbon footprint. Port decarbonization is an essential part of this process. As awareness and prevalence of environmental issues continues to grow, ports will have to level up to reduce their environmental impact. The International Maritime Organization has already set net-zero emission goals by 2050, for the entirety of international shipping. This is in alignment with the Paris Agreement, which calls for immediate emission reductions as well as net-zero greenhouse gas waste no later than 2050. In some countries, emissions cost the environment and businesses. The European Union has already instrumented fees for excessive CO2 emissions, adding financial pressure to reduce waste.

Read here more about the IMO Decarbonization on Maritime Emissions

Existing services, such as LionRock’s “Waste Free Shipping” offer a way for companies to save money while contributing to more sustainable maritime shipping. By tracking port traffic and reducing fuel waste, organizations save time and money alongside carbon dioxide waste that would have entered the atmosphere. Recent innovations, such as Techbinder and LionRock Maritime’s Smart Vessel Optimizer, aim to streamline the measurement of carbon emissions, making it accessible and actionable. As more companies use data and technological advancements, the shipping industry has the potential to become greener. Technology offers the solution to decarbonize ports in a smart way, by saving resources and lowering emissions. This trend will benefit everyone, but is especially good for the planet.

Book a consultation to accelerate your business’s decarbonization objectives.

As the maritime shipping industry strives to achieve net-zero emissions, the importance of port decarbonization cannot be overstated. Companies like Techbinder and LionRock Maritime are leading the charge, leveraging data and technology to reduce fuel inefficiencies. With innovative solutions, we save money and contribute to a cleaner, greener future for all. Join us in the journey towards more sustainable maritime shipping. Schedule a demo now to make your shipping or towage business more eco-friendly.

Frequently Asked Questions

What is the environmental impact of maritime shipping?

How can the shipping industry lower emissions?

What is port decarbonization, and why is it important for the maritime shipping industry?

What challenges are associated with implementing data-driven solutions for port decarbonization and the creation of green ports?

Related Topics

IMO Decarbonization on Maritime Emissions: Tugboat Compliance & Solutions Foto von Mika Baumeister auf Unsplash Navigating Regulatory Change In Decarbonization:…

References

Maritime Shipping- The International Council on Clean Transportation (2021)

A review of the port carbon emission sources and related emission reduction technical measures- Science Direct (2023)

Classifying maritime port emissions – Science Direct (2023)

Related Posts

The Role of AIS Tracking Systems in Enhancing Maritime Operations

The Role of AIS Tracking Systems in Enhancing Maritime Operations Photo by MICHAEL CHIARA – Unsplash AIS Marine Traffic – AIS Tracking …

Green Ports: Decarbonizing Ports through Data and make Ports more efficient Image by 12019 from Pixabay Green Ports: Decarbonizing Ports through Data …

Efficient Tugboat Fleet Management Analytics: Implementing a Tugboat Tracker System Photo by Elijah Mears on Unsplash Optimizing Tugboat Operations: The Power of …

Tugboat Industry Growth and Strategies: Navigating Emerging Markets with Data Insights

Tugboat Industry Growth and Strategies: Navigating Emerging Markets with Data Insights Foto von Dwi Cahyo auf Unsplash Navigating the Tugboat Industry: Trends, …