Value of tugboat speed optimization when using alternative fuels

Is tugboat speed optimization still relevant when using alternative marine fuels?

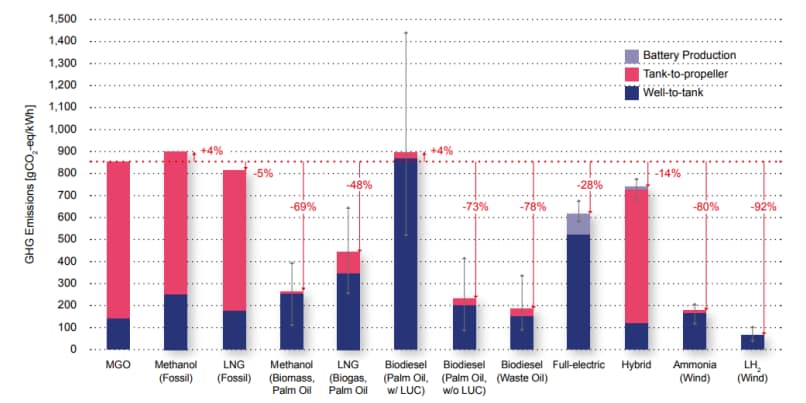

Tugboat operators are (gradually) transitioning to using alternative marine fuels than traditional diesel. Propelled by a call for urgent action to avoid climate change, the maritime industry as a whole is evaluating various options as a source of marine fuel. At LionRock we often get the question whether speed reduction to ECO speed for tugboats is still relevant once this transition to alternative fuels has been made in full. We asked 4 students (Arend Bijleveld, Benthe Kleinbekman, Daniel Mertens en Ante Simic) from the Rotterdam Mainport Institute to help us evaluate this question for a few of the main alternative fuels. We asked them to look at it from the view of cost, GHG emissions and practical considerations such as energy storage constraints. Here their conclusions for Hydrogen tugs, full electric tugs, Methanol based propulsion and finally LNG powered tugs.

Hydrogen

When looking purely at a Mega Joule per kilogram value, hydrogen comes out on top. With an energy density almost three times that of diesel, this would mean that much less hydrogen would be needed to do the same work. In addition, the carbon emissions of hydrogen, provided it is so-called “green hydrogen”, are zero. Theoretically, the emission of nitrogen oxides should also be zero, but in practice a certain amount is a certain amount is emitted anyway. The downside, however, is that storing hydrogen presents many challenges; in order to store it compactly in liquid form it must be stored under high pressure or extremely low temperatures. Furthermore, the cost of hydrogen is currently about two to six times the price of diesel. When the costs of hydrogen and diesel are compared with their energy densities, it can be concluded that saving is still relevant from a financial point of view. A major additional driver for speed optimization is the storage constraint.

Full electric

Sailing electrically means that the electric motors are powered by a battery pack that is charged from the shore when the tug is alongside. When using the energy from the battery packs, no emissions are released and an electric ship can easily sail within the future regulations. How sustainable it ultimately is, however, remains to be seen as it depends on how the electricity was previously generated. The cost will be somewhat lower than running on diesel, and therefore there the financial need will be low. However, again, a major driver for speed optimization is the limited energy storage capacity in batteries.

Methanol

Methanol has an energy density value about half that of diesel. In addition to the fact that the energy density of methanol is lower, the volumetric density is also lower compared to diesel. The combustion of methanol releases a similar amount of carbon dioxide as with diesel. However, the emission of nitrogen and sulfur oxides is drastically lower. As a result, methanol-fueled ships will meet future emissions regulations. One disadvantage of methanol is that it requires a larger fuel tank for the same endurance of the ship. Hence taking up more space on board. With the expected prices for methanol in the future, it is possible that sailing on methanol will become cheaper than sailing on diesel.

LNG

LNG possesses the highest energy density of the fuels discussed after hydrogen. In comparison with diesel, LNG has a higher energy density but a lower volumetric density. Storage of LNG must also take place at low temperatures because otherwise it would evaporate. LNG requires a number of modifications to the ship, the main ones being larger fuel tanks and a new fuel tanks and a new or rebuilt engine. The cost of one kilo of LNG is comparable to that of a kilo of diesel. Because the energy density is somewhat higher, the cost of LNG are slightly lower, the margins on fuel savings are smaller compared to diesel. However burning LNG also emits N20 which is a greenhouse gas 265 times more potent than CO2 so operators do well by keeping speeds as ECO efficient as possible.

Slowsteaming remains relevant. Contact us

From this review that the need for speed optimization remains relevant. Depending on the type of fuel used, the driver for speed optimization becomes different. It might be cost, the emissions or simply the energy storage space constraint.

References

RMIPIP01 – ADVIESRAPPORT by Arend Bijleveld, Benthe Kleinbekman, Daniel Mertens en Ante Simic