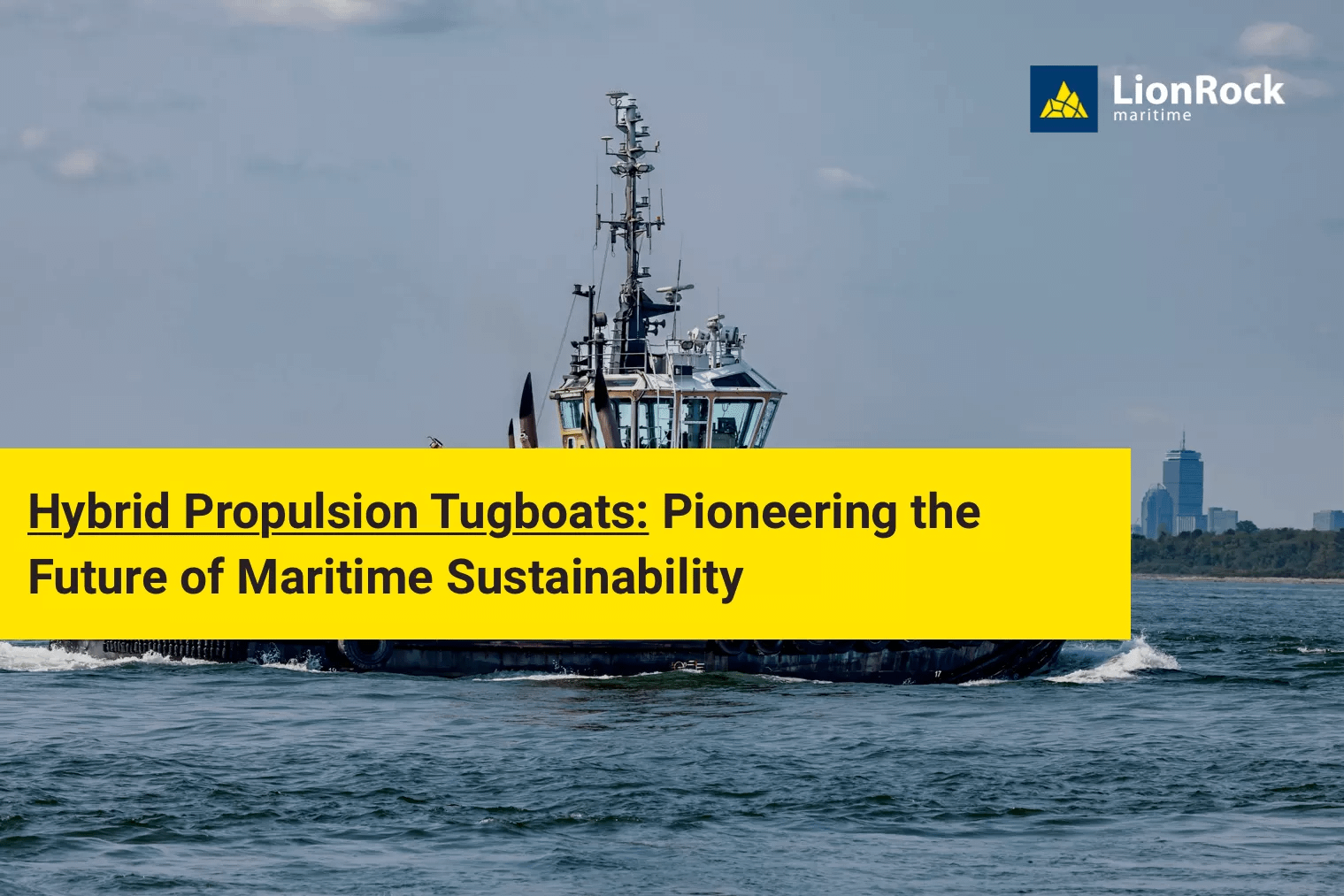

Hybrid Propulsion Tugboats: Pioneering the Future of Maritime Sustainability

Tag: CO2 reduction

Hybrid Tugboat: Pioneering the Future of Maritime Sustainability

An overview of the recent developments for green hybrid tugs

Hybrid propulsion tugboats are at the forefront of transforming the maritime industry. By integrating alternative fuels and cutting-edge propulsion technologies, these tugboats offer significant environmental and operational benefits.

The Paris Agreement of 2016 has intensified global efforts to reduce GHG emissions, making it a critical issue for the shipping sector. In response, the International Maritime Organization set ambitious goals in 2018 to halve GHG emissions from international shipping by 2050, with the ultimate goal of achieving zero emissions by the end of the century.

Therefore, hybrid propulsion comes into play because of its promise of reducing emissions. Hybrid vessels can operate on electrical power combined with conventional fuel or utilize a blend of traditional and alternative sustainable fuels. Tugboats, given their near-shore operations and regular recharging needs, were among the earliest maritime vessels to adopt battery technology. The first hybrid tugboats began operations as early as 2009, with fully electric, zero-emission models following in 2019.

This article explores the innovations in the field of hybrid green tugs, focusing on both the environmental and operational benefits, as well as the challenges. To do so, industry examples and case studies will be provided.

Hybrid Tugboat models through the years

Through the years, tugboats have increasingly relied on batteries and various fuels to reduce emissions and enhance efficiency.

In 2010, the US-based company Foss Maritime’s hybrid tugboat Carolyn Dorothy, powered by diesel engines and batteries, demonstrated significant environmental benefits. It retained the power and maneuverability of conventional tugs while dramatically reducing emissions, noise, and fuel consumption. The hybrid electric tugboat achieved a 73% reduction in particulate matter, 51% in nitrogen oxide, and 27% in carbon dioxide.

In 2015, NYK Line and IHI Power Systems Corporation developed Sakigake, the first Japanese LNG-fueled tugboat. Using LNG, Sakigake reduced sulfur oxide emissions by nearly 100%, nitrogen oxide by 80%, and carbon dioxide by 30% compared to heavy oil. Currently, IHI Corporation is working on developing a hybrid ammonia-powered tugboat. Ammonia, which emits no CO₂ when burned, shows promise as a next-generation fuel for reducing shipping’s environmental impact.

Another example of the industry’s commitment to innovation and sustainability is offered by Seabulk’s hybrid diesel-electric tugs Spartan and Titan. These new green hybrid tugs, which started to operate in the USA in 2022, combine the benefits of diesel and electric propulsion for enhanced efficiency and reduced emissions. They offer exceptional power and maneuverability, fitting the high-powered needs of their customers while improving fuel efficiency.

Another example is the Hydrotug 1, operating in Antwerp since 2024, which features dual-fuel BeHydro engines that run on hydrogen or traditional fuel. This tug is part of the Port of Antwerp-Bruges’ plan to transition to a climate-neutral port by 2050.

The Panama Canal Authority’s new hybrid tugboats are another example of the growing adoption of this technology in high-profile operations. In October 2023, the Authority contracted for ten hybrid electric tractor tugboats, aiming to reduce emissions during ship towage through the canal and docking in Panamanian ports. Corvus Energy plays a crucial role in the performance of these 30-meter long hybrid tugboats by supplying advanced battery systems. These battery systems enable the tugboats to operate efficiently and sustainably. Corvus Energy CEO, Fredrik Witte affirmed that the battery systems significantly decrease vessel emissions, supporting the Authority’s goal of achieving net-zero GHG emissions by 2050.

Finally, one last notable project that has yet to come to fruition is Svitzer’s methanol hybrid fuel cell tug. The company is designing the world’s first methanol hybrid fuel cell tug, aiming to combine the environmental benefits of methanol with the efficiency of fuel cells. This new hybrid electric tugboat is expected to enter operations in 2025, helping the port of Gothenburg to fulfil the ambitious target to reduce shipping emissions within the port area by 70% by 2030.

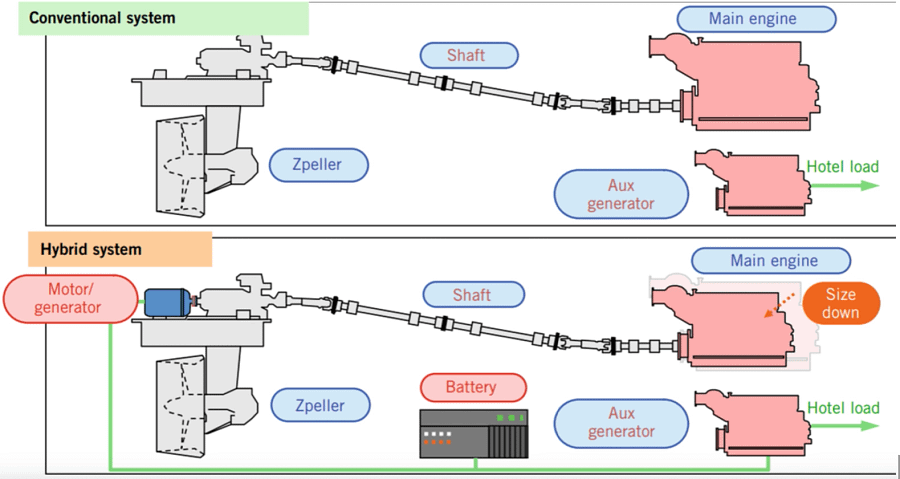

Comparing Conventional and Hybrid Propulsion Systems in Maritime Applications

Insights:

The graphic illustrates a comparison between conventional propulsion systems and hybrid propulsion systems for hybrid tugboat in maritime applications. The conventional system, depicted in the top diagram, consists of a main engine connected to a shaft, Zpeller, and an auxiliary generator to manage the hotel load. The hybrid system, shown in the bottom diagram, integrates a motor/generator and a battery into the propulsion chain. This system allows for a smaller main engine, with the motor/generator and battery providing additional power as needed. The auxiliary generator remains in place to handle the hotel load, while the hybrid configuration enhances efficiency and reduces emissions by optimizing the power sources.

The Challenges of adopting green hybrid tugs

The promises of adopting green hybrid tugboat are many, but there are also some downsides, both when it comes to hybrid electric tugboats which rely on batteries, and when the hybrids rely on non-conventional fuels.

The very first downside, for all hybrid tugboats, is the need to invest on two propulsion systems and their maintenance. In the case of electric hybrid systems, for example, these have higher start-up costs due to the expensive Battery Energy Storage Systems. Additionally, crew training for these highly automated systems can be costly. And the need for significant space to install batteries also adds to the vessel’s weight.

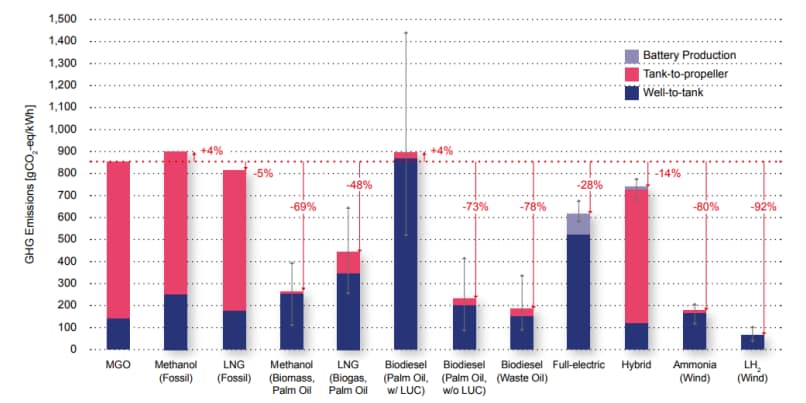

But, when it comes to relying on alternative fuels, instead, these might not be as green as expected. If Hydrotug 1 or the Japanese ammonia-fueled tugboat are taken in examination, it is arguable that their reliability on hydrogen is a downside because this is very energy-intensive to produce and difficult to transport. Despite this, hydrogen produces no emissions when burned, and it can even be produced in an entirely green way, through sustainable processes or renewable resources. This shows the importance of assessing “well-to-wake” and “tank-to-wake” emissions to understand the environmental impact of fuels when evaluating the performance of a hybrid tugboat.

But, apart from the disadvantages, the benefits of hybrid tugboats are the primary reasons why they are attracting owners and operators globally. And with thorough data analysis, research, and development, companies will be able to elevate the hybrid sector to its full potential.

Operational Profiles and Data Utilization

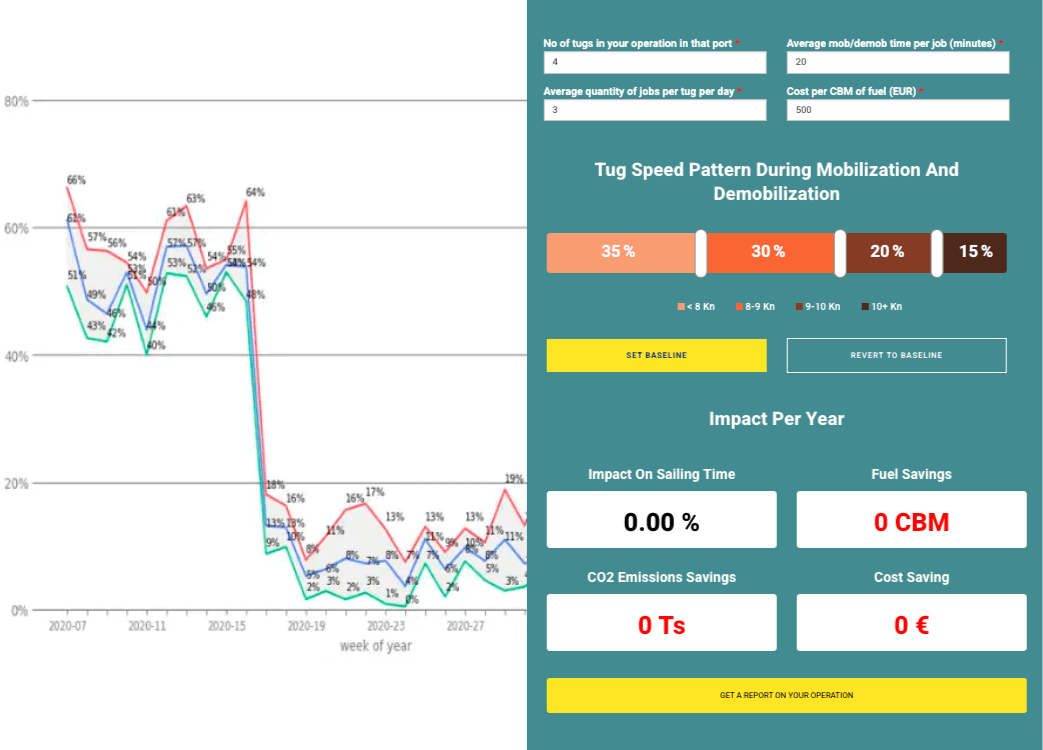

Hybrid propulsion technology has been deployed on tugboats to reduce emissions and enhance the efficiency of operation. The operational profile of a vessel plays a significant role in determining the efficiency and emissions of hybrid propulsion systems. By analyzing and optimizing these profiles, maritime operators can improve fuel efficiency and reduce emissions. Continuous monitoring and optimization of operational profiles are vital in achieving the full potential of hybrid tugboats. Doing this in the right way results in an improved performance of the ship in terms of fuel consumption, emission regulation, operational flexibility, and reduced noise and vibration.

Operational efficiency of hybrid electric tugboats can be improved, for example, by implementing power management strategies that are able to optimize the running hours of the engines to run them at optimum efficiency. Or also, by knowing when to change the primary source of energy for the propulsion between high and low-speed operations.

Conclusion - A Greener Future with Hybrid Propulsion

In conclusion, the potential of hybrid propulsion in reducing emissions and improving efficiency is immense. These green hybrid tugs have demonstrated benefits in lowering fuel consumption, cutting emissions, and improving operational performance. By integrating alternative fuels, advanced battery systems, and data analytics, hybrid tugboats can significantly lower their environmental impact while maintaining high operational efficiency.

Continuous innovation and effective data utilization are essential in maintaining and enhancing their performance. As the maritime sector increasingly pursues carbon reduction initiatives, the number of hybrid tugboats worldwide is projected to grow significantly. The maritime industry is poised for a greener future, driven by the adoption of hybrid propulsion technologies.

Achieve Sustainability with LionRock’s Waste Free Shipping Service

LionRock offers advanced solutions for maritime operations. The “Waste Free Shipping” service is designed to achieve lower emissions and eliminate waste. This service ensures that the tugboats operate sustainably, adhering to the highest environmental standards, by keeping their operational profile in check. LionRock’s Waste Free Shipping leverages cutting-edge technologies and comprehensive waste management strategies to minimize the environmental footprint of maritime operations.

Partnering with LionRock for Waste Free Shipping can help companies achieve sustainability and operational excellence. By leveraging LionRock’s expertise and innovative solutions, maritime operators can lead the way in creating a greener future.

Join us in transforming the maritime industry and making a positive impact on the environment. For more information on how LionRock can help you achieve waste-free and efficient maritime operations, visit LionRock Maritime’s Waste Free Shipping.

Frequently Asked Questions

What are the main benefits of using hybrid tugboats in the maritime industry?

What challenges are associated with adopting green hybrid tugs?

How do operational profiles and data utilization enhance the efficiency of hybrid electric tugboats?

What is the future outlook for hybrid tugboats in the maritime sector?

Related Topics

New Tugboat Software: A Fuel Consumption Monitoring Alternative | 2024 Photo by Steve Doig on Unsplash Revolutionizing Tugboat Fuel Efficiency:…

Efficient Tugboat Fleet Management Analytics: Implementing a Tugboat Tracker System Photo by Elijah Mears on Unsplash Optimizing Tugboat Operations: The…

References

- Joint R&D starts for practical application of ammonia-fueled tugboat – World’s first effort to achieve zero emissions from ships using ammonia fuel

- Corvus Energy to supply battery systems for 10 new hybrid tugboats servicing the Panama Canal

- World’s first hybrid tug even greener than initial estimates

- Seabulk welcomes its first hybrid diesel electric tug to towing fleet

- Hydrotug 1: the very first hydrogen-powered tug

- Svitzer designing world’s first methanol hybrid fuel cell tug

- Panama Canal Authority orders 10 hybrid-electric tractor tugboats

- Review on the challenges of hybrid propulsion system in marine transport system

- Understanding WELL-TO-TANK, TANK-TO-WAKE, and WELL-TO-WAKE EMISSIONS

Related Posts

How to Become a Tugboat Captain: A Comprehensive Guide | 2025

A Comprehensive Guide to a Rewarding Career in Maritime Operations How to become a Tugboat Captain Becoming a tugboat captain is more …

Shipping Alliances: Gemini Cooperation shifts tugboat demand in 2025

How Shipping Alliance Restructuring and Market Insights Shape Tugboat Demand and Fleet Optimization Introduction – Change Within Shipping Alliances and Its Impact …

The Business of Towing: Job Costing Insights

Cost to serve on tugboat jobs In the competitive world of maritime services, understanding the cost to serve is crucial for towage …

Diesel Tugboats and Advanced Biofuel: An In-Depth Look at the Integration of Biodiesel

Introduction – Biofuel to power diesel tugboats The maritime industry is undergoing a significant transformation as the European Green Deal and the …