Hydrotug: Data-driven impacts of Hydrogen-powered Tugboats

Hydrotug: Data-driven impacts of Hydrogen-powered Tugboats

Hydrotug. With this article, we examine alternative fuels for tugboats, the production, and sustainability of hydrogen, its emissions profile, and the operational benefits and challenges of hydrogen-powered tugboats, exploring the potential of hydrogen as a sustainable marine fuel.

A close look into the recent data of the Hydrotug

Innovative solutions are emerging to meet stringent environmental standards as the maritime industry faces increasing pressure to reduce its carbon footprint. Among these solutions is the Hydrotug 1, the world’s first hydrogen-powered tugboat, which represents a significant step forward in the sustainable operation of the maritime industry. This article examines the viability of hydrogen as a marine fuel, the methods used to produce it, the comprehensive emissions profile from production to operation, and the practical benefits and challenges faced by thehydrotug.

Exploring Alternative Fuels for Tugboats

The maritime industry is actively researching a wide range of alternative fuels to replace the traditional diesel fuel used in tugboats, with the aim of reducing emissions and improving sustainability. Among the fuels being considered for this transition are hydrogen, methanol, synthetic diesel, ammonia, biofuels, and batteries. Hydrogen has the advantage of zero emissions at the point of use and high efficiency, making it an attractive option for the future. However, it requires new infrastructure for production, storage, and distribution. It also poses handling and safety challenges due to its high flammability. Additionally, hydrogen has a lower energy density compared to traditional diesel, which means larger storage volumes are needed onboard vessels, posing further logistical challenges.

Methanol can be stored and transported as a liquid at ambient temperatures, using existing infrastructure, and has a higher energy density than hydrogen. However, methanol combustion still produces CO2, although less than conventional diesel. Without significant changes to existing engines or infrastructure, synthetic diesel can seamlessly replace conventional diesel. However, its production is energy intensive and often relies on fossil fuels, which can offset its environmental benefits.

Another promising candidate is ammonia, with its high-energy density and carbon-free combustion. However, ammonia is highly toxic and corrosive. It requires stringent safety measures for storage and handling.

Biofuels offer a renewable and potentially carbon-neutral option, derived from organic materials such as vegetable oils, animal fats and waste biomass. They are an attractive transitional fuel because they can frequently be used in existing diesel engines with little or no modification. The carbon dioxide released when they burn is roughly equivalent to that absorbed while growing the biomass, making biofuels more sustainable than fossil fuels. However, biofuel production can compete with food resources and lead to deforestation if not managed sustainably. This poses significant challenges in balancing food security and environmental impacts.

Battery electric tugs offer a zero-emission solution at the point of use. They can use renewable energy sources for recharging. However, the energy density of batteries is lower than that of liquid fuels, which results in a shorter range and longer refueling times. Furthermore, the environmental impact of manufacturing and disposing of batteries must be considered. Choosing an alternative fuel means balancing these factors to achieve the best environmental and operational outcomes. Ongoing research and technological advances will continue to shape the future of marine propulsion.

Hydrogen Production: Pathways and Sustainability

Hydrogen can be produced in numerous ways, each with varying degrees of sustainability. Green hydrogen, produced by electrolysis using renewable energy sources such as wind, solar or hydroelectric power, is the most sustainable option. This process splits water into hydrogen and oxygen, with zero emissions if the electricity used is renewable. Green hydrogen represents the pinnacle of sustainability. It aligns perfectly with global decarbonization goals and provides a truly clean fuel alternative for the maritime industry.

In contrast, a significant proportion of hydrogen today is produced by steam methane reforming (SMR). This involves reacting natural gas with steam to produce hydrogen and CO2. This method, which is often referred to as gray hydrogen, results in a significant amount of greenhouse gas emissions. Blue hydrogen offers a slightly greener alternative by capturing and storing the CO2 produced during SMR, but the process still relies on fossil fuels and the effectiveness of carbon capture and storage (CCS) technologies.

Another emerging method is turquoise hydrogen, which is produced by the pyrolysis of methane and produces solid carbon instead of CO2. If the carbon by-product can be effectively used or stored, this method has the potential to reduce emissions. However, it is less sustainable than green hydrogen because, like blue hydrogen, it relies on natural gas.

The sustainability of hydrogen as a marine fuel depends on the method of production. Green hydrogen, which has the potential for zero upstream emissions, emerges as the ideal solution. However, the transition to green hydrogen will require significant investment in the infrastructure for renewable energy sources and in electrolysis technology. Hybrid approaches combining different production methods may be necessary during the transition period. Ultimately, the development of renewable energy capacity and the efficiency of electrolysis will be critical to making hydrogen a truly green solution for the maritime industry.

Well-to-Wake Emission Profile of Hydrogen as a Marine Fuel

The well-to-wake emission profile of a fuel covers its entire life cycle, from its production (upstream) to its combustion (downstream). This comprehensive assessment is essential to understand the true environmental impact of hydrogen as a ship fuel. Hydrogen’s well-to-wake emissions are significantly lower than those of conventional marine fuels. This is especially true when produced using renewable energy.

Green hydrogen, which is produced by electrolysis using renewable energy sources, offers the cleanest emissions profile. The only by-products of its production are oxygen and heat, both of which have a minimal impact on the environment. At the point of use, hydrogen fuel cells emit only water vapor. There are no CO2, NOx or particulate emissions. This makes green hydrogen an exceptionally clean fuel throughout its lifecycle.

However, the emission’s profile is different for hydrogen produced from fossil fuels, such as gray or blue hydrogen. The production process for gray hydrogen is a significant source of CO2 emissions, which can outweigh the downstream benefits. Blue hydrogen aims to mitigate this by capturing CO2 during production. However, overall sustainability depends on the efficiency and reliability of carbon capture and storage technologies.

The energy density is another critical factor in the assessment of the viability of hydrogen as a marine fuel. Hydrogen has a lower volumetric energy density than conventional fossil fuels. This means that it requires larger storage volumes or higher pressures. This can have an impact on the design and operation of hydrogen-powered vessels and will require advances in storage technology and vessel design in order to optimize efficiency. Especially on tugboats that have limited space, this poses a challenge.

The understanding and optimization of hydrogen’s well-to-wake emissions is critical to the assessment of its true environmental impact. Green hydrogen offers a way to significantly reduce the maritime industry’s carbon footprint. However, the transition requires careful consideration of production methods and technological advances to maximize its benefits.

Operational Benefits and Challenges of Hydrogen-powered Tugboats

Hydrogen-powered tugboat, such as the Hydrotug 1, offer significant operational advantages as well as considerable challenges. One of the most important of these benefits is the significant reduction in emissions. Fuel cells emit only water vapor, which eliminates CO2, NOx and particulate emissions where they are used. This contributes to cleaner air in port cities and coastal areas, which is in line with stringent environmental regulations and improves public health outcomes.

In addition, noise pollution in ports and harbors is reduced because hydrogen fuel cells operate more quietly than conventional diesel engines. This quieter operation can improve the working environment for crew members and contribute to the overall sustainability of the port.

However, the operational challenges of a hydrogen-powered tugboat are significant. One of the main challenges is the lower energy density of hydrogen compared to traditional marine fuels. Hydrogen has a higher space requirement for storage, which has implications for vessel design and cargo capacity. High-pressure tanks or cryogenic storage solutions are required to store sufficient hydrogen on board. This adds complexity and cost to vessel design and operation.

The need for specialized refueling infrastructure is another challenge. Ports will need to invest in facilities for the production, storage, and distribution of hydrogen to support hydrogen-powered vessels. This will require a significant capital investment as well as co-ordination between port authorities, shipping companies and energy providers. Safety is also a critical issue due to hydrogen’s flammability and the need for strict safety protocols during storage and handling.

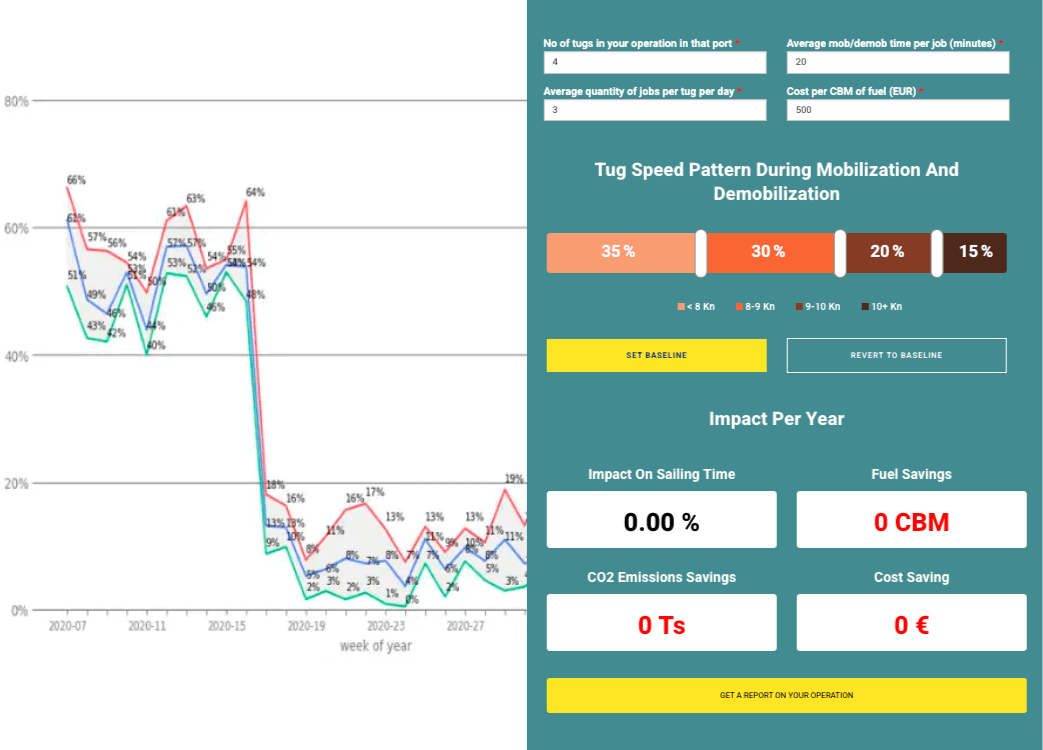

Despite these challenges, data-driven evaluation of hydrogen-powered tugboats has shown promising results. The Hydrotug 1, for example, has demonstrated effective performance in reducing emissions and improving operational efficiency. Ongoing data collection and analysis will be essential for the optimization of fuel consumption, the improvement of operational profiles and the enhancement of the overall viability of hydrogen-powered tugboats.

Conclusion about the Hydrotug

In conclusion, hydrogen-powered tugboats offer a solution for reducing the maritime industry’s carbon footprint. While challenges related to energy density, infrastructure, and safety remain, advancements in technology and data-driven insights will play a crucial role in overcoming these hurdles. It will be interesting to see how practical experiences with Hydrogen tugboats, like The Hydrotug 1 develop to test the potential of hydrogen-powered vessels, and if they can set a precedent for future innovations in maritime sustainability.

Partner with LionRock Maritime for Sustainable Port Operation

If you would like to see more about the actual Hydrotug 1 operational use and / or understand your own operational profile and viability of Hydrogen for your operations, schedule a meeting with us.

FAQ: Hydrotug

What are the alternative fuels for tugboats?

The maritime industry is exploring various alternative fuels to replace traditional diesel in tugboats, including hydrogen, methanol, synthetic diesel, ammonia, biofuels, and batteries. Hydrogen stands out due to its zero emissions at the point of use and high efficiency. However, it requires new infrastructure for production, storage, and distribution, and poses safety challenges due to its high flammability. Other fuels like methanol and synthetic diesel can utilize existing infrastructure but still produce some CO2 emissions. Ammonia is carbon-free but toxic and corrosive. Biofuels are renewable but can compete with food resources, and battery-electric options have lower energy density and longer refueling times.

How is hydrogen produced and how sustainable is it?

Hydrogen can be produced through several methods, with varying sustainability levels. Green hydrogen, produced via electrolysis powered by renewable energy sources (wind, solar, or hydropower), is the most sustainable, as it generates zero emissions if renewable electricity is used. Gray hydrogen, produced through steam methane reforming (SMR), results in significant CO2 emissions. Blue hydrogen captures and stores the CO2 produced during SMR, offering a slightly greener alternative. Turquoise hydrogen, produced via methane pyrolysis, generates solid carbon instead of CO2 but still relies on natural gas. Green hydrogen is ideal for sustainability, though transitioning to it requires significant investment in renewable energy and electrolysis technology.

What is the well-to-wake emission profile of hydrogen as a marine fuel for hydrogen tugboat?

The well-to-wake emission profile of hydrogen encompasses its entire lifecycle, from production to combustion. Green hydrogen offers the cleanest emission profile, with water vapor as the only byproduct at the point of use. Hydrogen produced from fossil fuels, such as gray or blue hydrogen, has higher upstream emissions due to the CO2 produced during their production processes. Understanding and optimizing the well-to-wake emissions of hydrogen is crucial for assessing its true environmental impact and making informed decisions about its use as a marine fuel.

What are the operational benefits and challenges of using hydrogen tugboats?

Hydrogen-powered tugboat boats offer significant benefits, including substantial reductions in emissions and quieter operation compared to traditional diesel engines. These benefits align with stringent environmental regulations and improve public health outcomes in port cities. However, challenges include hydrogen’s lower energy density, which requires more space for storage, and the need for specialized fueling infrastructure. High-pressure tanks or cryogenic storage solutions are necessary, adding complexity and cost. Safety protocols for handling hydrogen are also critical due to its flammability. Despite these challenges, data-driven assessments show promising results, with the Hydrotug 1 demonstrating effective performance in emissions reduction and operational efficiency.

References for Hydrotug

- https://www.researchgate.net/publication/358208884_Life_cycle_assessment_of_diesel_and_hydrogen_power_systems_in_tugboats

- https://www.oceansciencetechnology.com/news/hydrogen-powered-tugboat-ready-for-operation/

- https://newsroom.portofantwerpbruges.com/hydrogen-powered-tug-is-world-first-for-port-of-antwerp

- https://www.marinelink.com/news/worlds-first-hydrogenpowered-tugboat-510082

- https://www.est-floattech.com/projects/elektra-first-hydrogen-canal-tug/

- https://www.marinelog.com/news/worlds-first-hydrogen-fueled-tugboat-launched/

- https://maritime-executive.com/article/world-s-first-hydrogen-powered-tugboat-ready-to-begin-operations

- https://www.mtu-solutions.com/na/en/stories/marine/commercial-vessels/technology-turnaround-which-fuel-for-the-tugboats-of-the-future.html

- http://foss-maritime.com/press-releases/worlds-first-hybrid-tug-even-greener-than-initial-estimates/

Image References

Recent Blog Posts about Tug Boat Cost Management and Efficiency

- Hydrotug: Data-driven impacts of Hydrogen-powered Tugboats

- Emission Abatement Systems – AES to reduce Tugboat Emissions

- Transforming Tugboat Fuel Efficiency with Machine Learning: A Comprehensive Whitepaper

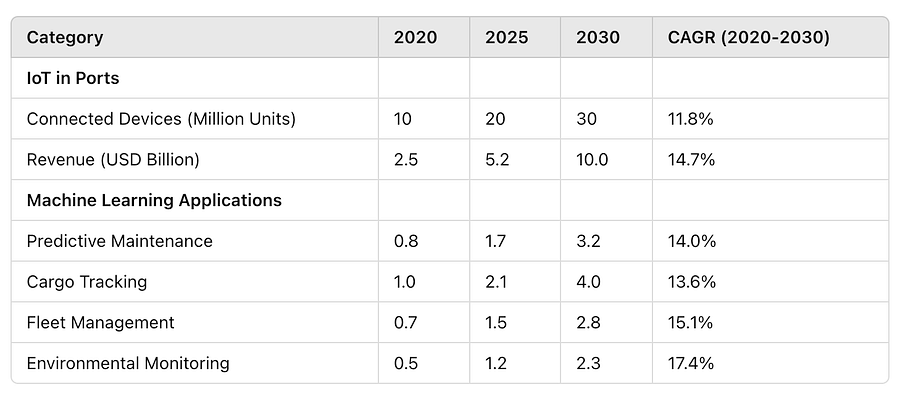

- The Impact of CSRD and ESRS on Maritime Sustainability Reporting

- Green Ports: Decarbonizing Ports through Data and make Ports more efficient

- IMO Decarbonization on Maritime Emissions: Tugboat Compliance & Solutions