The Path to Decarbonization: Tracking CO2 Emissions from Tugboats

Decarbonization Journey: Monitoring Tugboat CO2 Emissions in Ports

Tracking the journey towards reduced shipping emissions, through tugboats.

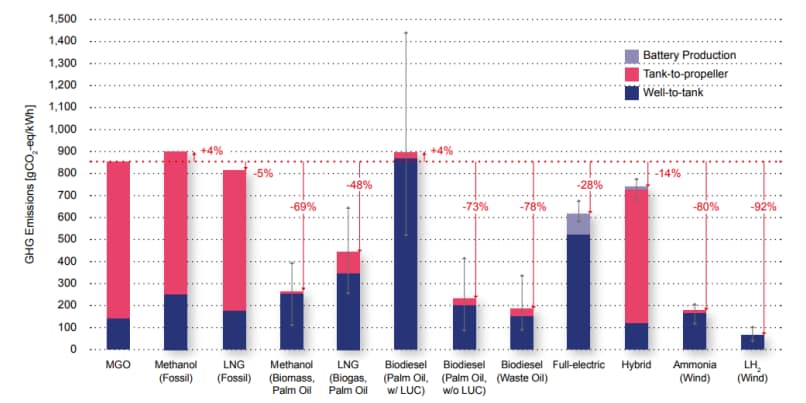

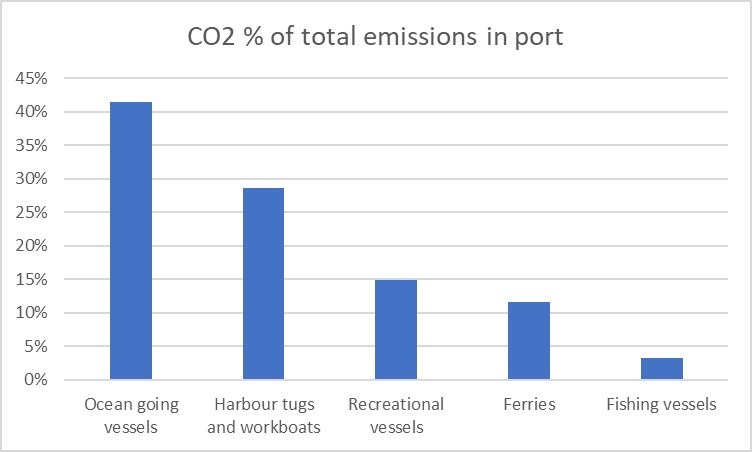

The effects of climate change are increasing the urgency of all sectors to curb their emissions, including the maritime industry. Organizational bodies and governments are increasing the pressure and incentive to do so. The International Maritime Organization (IMO) has set net-zero greenhouse gas emission goals by 2050, and the EU-ETS system has enacted fees for excessive maritime CO2 emissions. With these high goals, smaller pieces of shipping, such as tugboats, are often overshadowed by larger vessels. Yet, tugboats are an opportunity for substantial reductions in shipping emissions.

A Critical Path to Sustainability: Measurement and Monitoring

International waste requires an international approach. That’s why organizations such as the IMO have instated the 2050 goal, with checkpoints along the way. The soonest checkpoint is 2030, with a 40% reduction in greenhouse gas emissions as compared to 2008. In addition to international commitments, local ports have also become focal points for emissions reductions.

Achieving these goals has its own set of challenges between operational, technical, and financial barriers. For ports, these challenges often center around upgrading infrastructure and implementing advanced emissions-reducing technologies, while being transparent about the success of these efforts.

The unique challenges for towage companies in this respect include issues of operational efficiency and cost barriers. Energy-efficient technologies typically come with high upfront costs, making it challenging to align with short-term business objectives.

While facing these barriers, tugboat companies must also comply with new 2023 regulations. These operators are required to track their Energy Efficiency Existing Ship Index (EEXI) ratings, though only for their tugs exceeding 400 GT. Moreover, offshore vessels over 400 GT (which a selection of tugs will fall under) operating in the EU will also be subjected to the EU-MRV scheme to measure and report emissions.

Accurate measurement and monitoring of tugboat decarbonization is crucial for carbon reduction. In order to reduce emissions from ships, they need to be tracked, recorded, and monitored to accurately report numbers and define the best reduction practices.

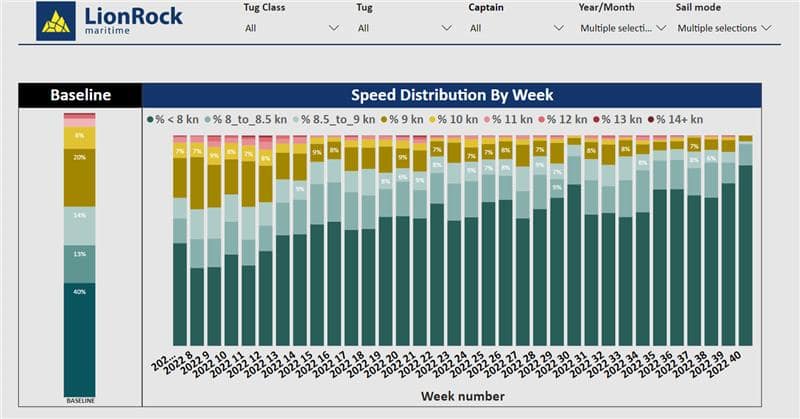

The unique characteristics of tugboats and their varying operations make compliance with standard regulations like EEXI and EU-MRV challenging. These systems often look at the power used per the size of the vessel. Tugboats, however, are typically comparable in size, but have strong variance in power (and fuel consumption) which means a GT to fuel consumption is meaningless for this class. For tugboats, transitioning to lower emissions requires detailed understanding of these ships’ unique operational profiles. Tugboats operate in short bursts of high-intensity, meaning that traditional metrics meant for long-distance vessels are not entirely transferable. To ensure this data is relevant and actionable, it must be tailored to the tugboats themselves.

Certification and Compliance: Ensuring a Sustainable Legacy

Validating Green Milestones

Certification allows for proof of sustainable progress. This means standardized metrics for emissions measurement and reporting are essential. The industry relies on tools like the International Maritime Organization’s (IMO) Data Collection System for fuel oil consumption of ships to guide this process. These systems ensure that emission reductions are not just claimed, but verified and recognized globally, contributing to a transparent and accountable shift towards greener operations.

Adhering to a Greener Code

Compliance with regulations, such as the IMO’s upcoming EEXI and CII metrics, anchors sustainable practices in legality. Tugboat operators are required to keep pace with these regulations, which act as both directives and benchmarks for the industry’s environmental efforts. The EEXI serves as a measure of a ship’s energy efficiency, while the CII tracks the operational carbon intensity. These regulations form a framework that compels operators to invest in cleaner technologies and operational practices that reduce emissions, ensuring a collective move towards a greener maritime future.

Decarbonizing Ports: Overcoming Challenges in Tugboat Emission Tracking

Tracking emissions is a necessary step towards a greener shipping industry. However, tracking emissions on tugboats is certainly not an overnight process. Operational, financial, and technological barriers have all slowed down the process at one point or another.

Certain equipment used to track emissions can be bulky or expensive. With a 25-year average lifespan, there may not be a lot of incentive to spend the money, or have a tugboat out of operation, for an older boat. This slows down both port decarbonization, and reaching the IMO goals.

Not all tugboat technology has been able to combat these issues, while ensuring accurate and beneficial information for the company. Spending time and money on soon-to-be outdated technology isn’t an attractive company decision. However, as the shift to greener ports quickens, so have technological adaptations. The barriers to emission tracking are all connected. By improving one area, technology, the other burdens, financial and operational, become easier.

To comply with the regulatory guidelines, tugboat companies need access to quality technology. Luckily for them, it’s easy to access.

LionRock Maritime's Vanguard Role in Green Towage

New emission goals cannot be met with old methods. To meet the IMO’s 40% reduction target by 2030, tugboat operators must improve their EEXI and CII metrics as fast as new technology allows them too. This is why new, advanced data is an essential part of reducing port emissions for towage companies.

Companies such as LionRock Maritime are paving the way in maritime decarbonization with data-driven solutions. They use technology, algorithms, and data in tailor-made offerings for towage companies, providing operations with the necessary data analytics to establish accurate emission baselines. Their packages, such as “Waste Free Shipping” help towage companies by lowering costs, and help the environment by lowering carbon emissions. No initial devices or investments are needed to obtain it, meaning that company tugs don’t have to sit out of operation. LionRock Maritime helps lower a financial barrier to emission tracking by using their new technology. With them, companies are able to align their strategies with IMO standards with a transparent data-driven approach.

Innovative Solutions for Enhanced Operational Efficiency

Understanding the distinct energy patterns of tugboats is critical for achieving emission reductions. LionRock Maritime understands this importance in their “Port Exploration” package. The goal of this package is to reduce fuel consumption, specifically in tugboat services. Using LionRock developed algorithms and predictive models, optimal route planning and fuel consumption analytics are made easily accessible. This tool empowers companies to make real-time decisions that can drastically reduce emissions. When integrated into a towage company’s existing operational framework, the technological tool encourages more efficient tugboat sailing behaviors without imposing a burden on management teams. LionRock Maritime works with tugboat companies, to take the path to lower emissions and save costs together.

You can schedule a meeting with our representatives and get a consultation on how you can achieve a better operational efficiency: Schedule a Call now.

Strategic Compliance and Market Competitiveness

Compliance with evolving regulations is not just about adherence in business, it’s’ about a competitive edge. LionRock Maritime’s insights into towage markets and operational benchmarks empower operations to exceed regulatory standards, enhancing their market position. By providing a clear roadmap for sustainable growth and operational excellence, LionRock Maritime’s services support tugboat sector operators in forming a legacy of sustainability.

Navigating Towards a Greener Maritime Future

Maritime decarbonization needs to be addressed from all angles. This means that ports, and the role that tugboats play in international shipping, are as important to the environmental movement as any. By using and supplying companies with the data and technology they need to track and lower their carbon emissions, steps are taken to meet the IMO’s goals. LionRock Maritime helps with their “Waste Free Shipping” Report to do this through their highly developed and easily accessible packages, setting a sustainability standard within the maritime sector, through tugboats.

If you want to take your tugboat operations towards a more efficient, eco-friendly horizon, contact LionRock Maritime to chart your course towards maritime decarbonization.

References

- The International Maritime Organization’s strategy on reducing greenhouse gas emissions from ships: IMO’s GHG Strategy

- Research articles on the technological advancements in tugboats and their impact on emissions: ResearchGate – Tug Boats

- Articles discussing the decarbonization of the shipping sector and the specific role of tugboats: LinkedIn Articles

- Detailed analysis of fuel usage and CO2 emissions from tug boat fleets: ResearchGate – Fuel Usage and CO2 Emissions

- LionRock Maritime’s services that assist in tracking and reducing emissions: LionRock Maritime

- The role of alternative fuels and propulsion systems in decarbonizing maritime operations: Alternative Fuels and Propulsion

- EU Climate Action on reducing emissions in the shipping sector: EU Climate Action – Shipping

- The International Maritime Organization (IMO) website, which offers information on the latest regulations, including the Energy Efficiency Existing Ship Index (EEXI) and the Carbon Intensity Indicator (CII).

- DNV GL’s maritime pages, which provide insights into compliance and certification processes for shipping companies.

- Lloyd’s Register’s maritime section, where you can find resources on ship efficiency and environmental regulations.

- Academic journals such as Marine Policy and The International Journal of Maritime Engineering for peer-reviewed articles on maritime regulation and technology.

Frequently Asked Questions

What role do emissions from ships play in global climate change?

How can maritime CO2 emissions be measured and reduced effectively?

What is maritime decarbonization, and why is it important?

Can you explain the regulatory framework guiding maritime decarbonization?

Related Posts

The Impact of CSRD and ESRS on Maritime Sustainability Reporting

The Impact of CSRD and ESRS on Maritime Sustainability Reporting Photo from Ronan Furuta The Impact Of CSRD And ESRS On Maritime …

The Role of AIS Tracking Systems in Enhancing Maritime Operations

The Role of AIS Tracking Systems in Enhancing Maritime Operations Photo by MICHAEL CHIARA – Unsplash AIS Marine Traffic – AIS Tracking …

Green Ports: Decarbonizing Ports through Data and make Ports more efficient Image by 12019 from Pixabay Green Ports: Decarbonizing Ports through Data …

Efficient Tugboat Fleet Management Analytics: Implementing a Tugboat Tracker System Photo by Elijah Mears on Unsplash Optimizing Tugboat Operations: The Power of …

Tugboat Industry Growth and Strategies: Navigating Emerging Markets with Data Insights

Tugboat Industry Growth and Strategies: Navigating Emerging Markets with Data Insights Foto von Dwi Cahyo auf Unsplash Navigating the Tugboat Industry: Trends, …

New Tugboat Software: A Fuel Consumption Monitoring Alternative | 2024

New Tugboat Software: A Fuel Consumption Monitoring Alternative | 2024 Photo by Steve Doig on Unsplash Revolutionizing Tugboat Fuel Efficiency: A Data-Driven …

IMO Decarbonization on Maritime Emissions: Tugboat Compliance & Solutions

IMO Decarbonization on Maritime Emissions: Tugboat Compliance & Solutions Foto von Mika Baumeister auf Unsplash Navigating Regulatory Change In Decarbonization: Implications For …

The Path to Decarbonization: Tracking CO2 Emissions from Tugboats

The Path to Decarbonization: Tracking CO2 Emissions from Tugboats Photo by Anton Khatkevich Decarbonization Journey: Monitoring Tugboat CO2 Emissions in Ports Tracking …